Bestsourcing Agents and the Shift to Low-Carbon Manufacturing

Global pressure to decarbonize supply chains is accelerating. Manufacturers are actively exploring greener practices as both regulatory frameworks and consumer expectations demand action. For U.S. companies seeking scalable solutions, low-carbon manufacturing has moved from an option to a requirement. This shift is changing how and where businesses source their products.

Navigating this new landscape requires more than supplier directories. It demands on-the-ground insight, factory vetting, and accountability. That’s where a bestsourcing agent becomes indispensable. These sourcing professionals are central to helping companies locate manufacturers with sustainable operations, reduce emissions across transport channels, and remain compliant with evolving environmental laws.

Why Low-Carbon Manufacturing Is a Priority

Carbon reduction targets from governments and large corporations are influencing sourcing decisions at all levels. Europe’s Carbon Border Adjustment Mechanism (CBAM) and the U.S. SEC’s climate disclosure rule are two high-impact policies affecting international trade. Brands that fail to align with low-carbon supply chain partners may soon face penalties, delays, or reputational damage.

Businesses are under pressure to disclose Scope 3 emissions. These include the indirect environmental impacts from suppliers. Partnering with a bestsourcing agent Asia gives importers real-time access to factory certifications, green manufacturing capabilities, and documentation needed for compliance reporting.

Regional Shifts Favoring Sustainable Production

Many Asian manufacturers are upgrading production facilities to include renewable energy sources, closed-loop systems, and resource-efficient technologies. Countries like Vietnam and Indonesia are gaining traction among U.S. buyers for their investment in sustainable industrial parks and green energy policies.

A bestsourcing agent based in these regions is well-positioned to connect buyers with vetted suppliers who align with low-carbon priorities. Agents also ensure that commitments made on paper are actually reflected in day-to-day operations—an important safeguard for procurement teams.

Freight and Logistics: The Carbon Cost Connection

While production methods are under scrutiny, transportation contributes a large share of total emissions. The rise in intermodal shipping, slow steaming strategies, and rail alternatives is pushing logistics to evolve. Many sourcing agents are integrating emission-aware shipping into their services, recommending ports or carriers based on carbon performance.

Working with a bestsourcing agent Asia can reduce a product’s carbon footprint through better freight planning and consolidation. They help clients avoid inefficient transits and identify low-emission alternatives where feasible.

Digital Tools and Verification Matter

One of the biggest challenges in low-carbon manufacturing is verification. Claims without proof carry reputational risks. Sourcing agents play a crucial role in collecting third-party environmental audits, energy usage reports, and carbon intensity indexes. These insights support procurement teams in tracking sustainability metrics and preparing for ESG reporting.

Today’s bestsourcing agent operates more like a partner in carbon intelligence. Their digital systems track supplier emissions, certifications, and energy sources—data that purchasing teams require when evaluating long-term contracts or ESG scorecards.

U.S. Brands Under Growing ESG Pressure

Major U.S. corporations are publicly committing to climate targets. As a result, they expect every link in their value chain to follow suit. Brands are increasingly rejecting factories that lack emissions records or energy improvement plans. Procurement departments are prioritizing agents who understand sustainable benchmarks and can ensure compliance at the source.

A bestsourcing agent Asia understands these evolving expectations. Their local oversight enables direct auditing and continuous monitoring, reducing the need for costly external consultants.

Challenges in Low-Carbon Transitions

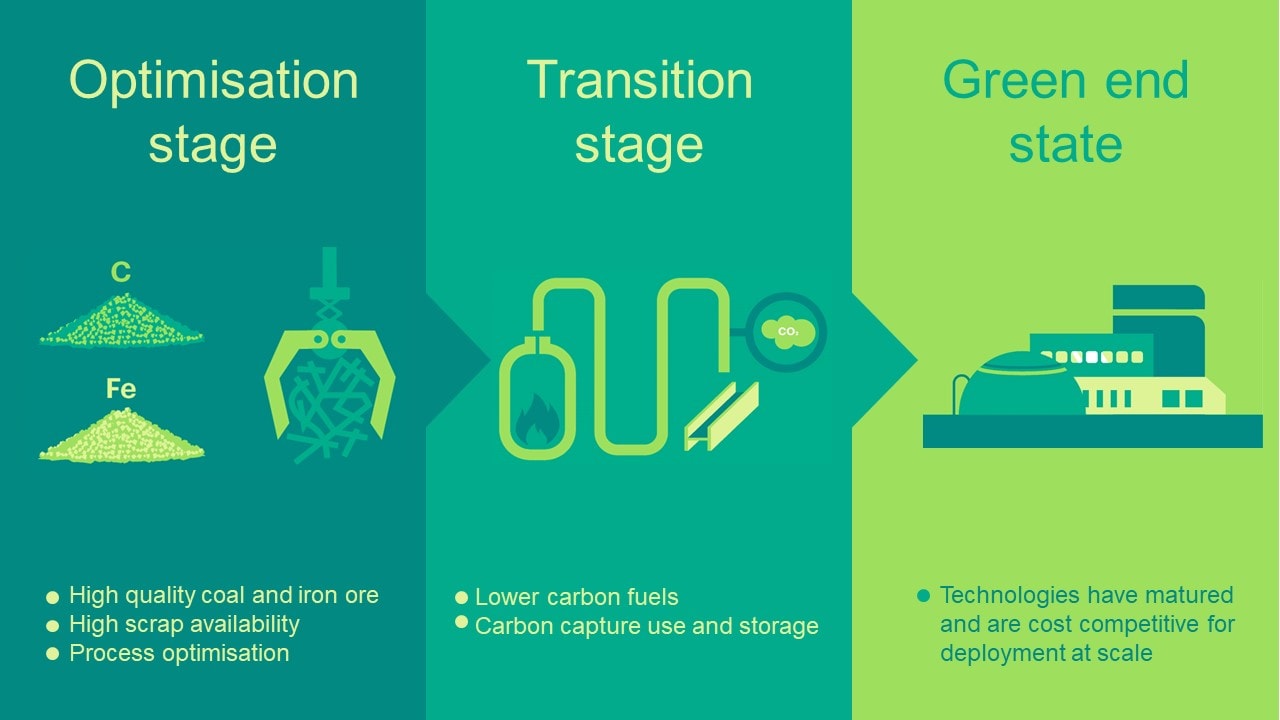

Despite increasing demand, many factories still operate under outdated practices. Equipment upgrades, alternative energy investments, and waste system improvements require capital. Sourcing agents help bridge this gap by identifying which suppliers are in active transition and which are falling behind.

Working closely with a bestsourcing agent allows companies to prioritize partners that are serious about emissions reduction. This insight ensures investments go toward building ethical and sustainable supply lines rather than supporting legacy inefficiencies.

Procurement Strategy in the Climate Era

Procurement must now serve both operational and sustainability goals. This balance is difficult without local visibility and supplier transparency. Sourcing agents provide this visibility while offering additional services such as real-time inspections, document validation, and ongoing compliance tracking.

Having a bestsourcing agent Asia on the ground accelerates adoption of low-carbon strategies without sacrificing delivery timelines or product quality. This agility is a competitive advantage as buyers worldwide align with sustainability directives.

Conclusion

Low-carbon manufacturing is shaping the future of global sourcing. Companies seeking long-term resilience, regulatory alignment, and ethical branding are working with experts who can help them reach greener partners. A skilled bestsourcing agent offers a roadmap to credible, carbon-conscious suppliers while minimizing operational friction.

This is not a temporary shift. It is the future of manufacturing strategy. Working with a trusted bestsourcing agent Asia ensures your sourcing approach evolves with the sustainability goals of tomorrow’s supply chain.